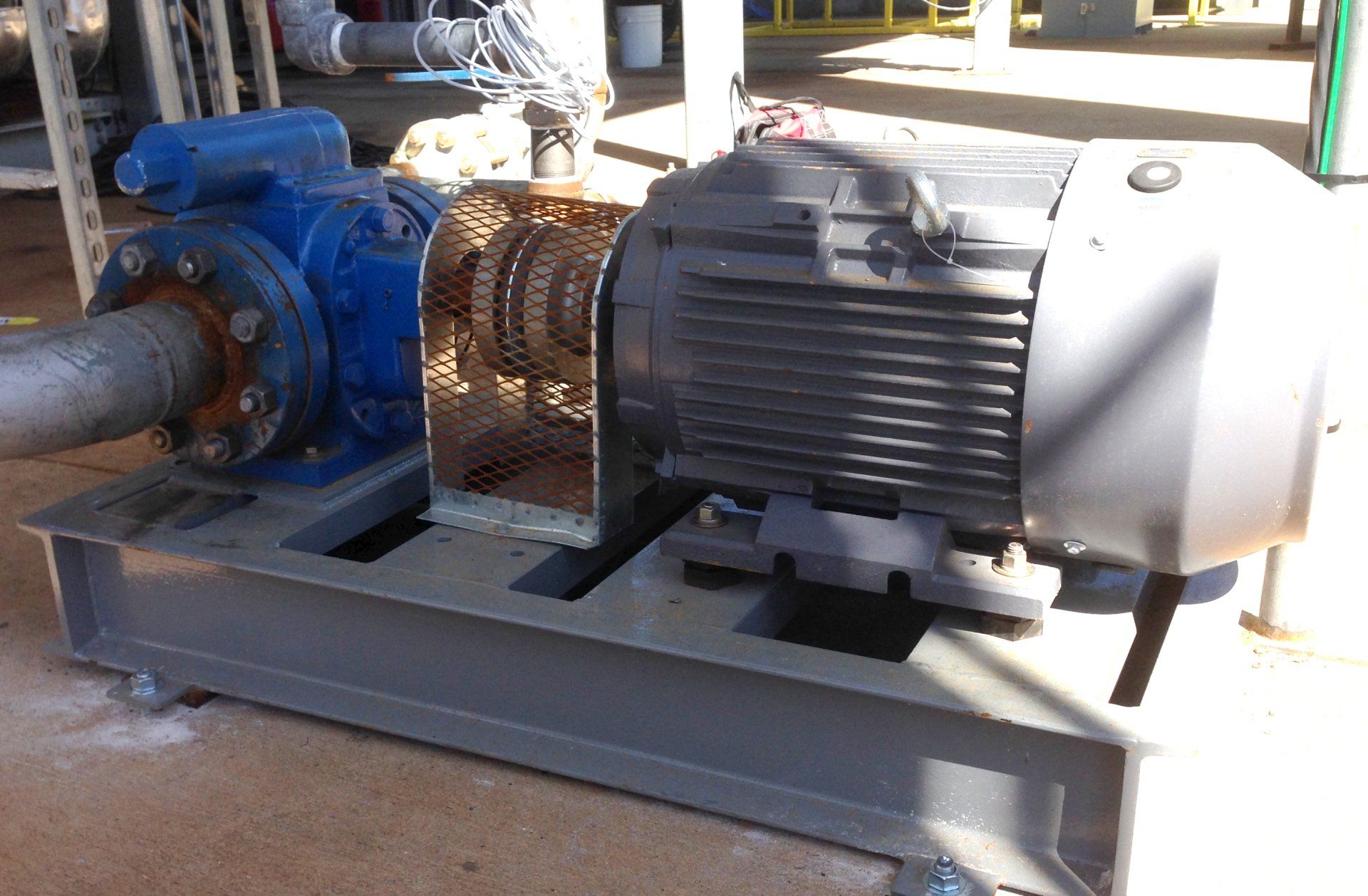

RotaChocks used in Pump Applications

RotaChocks used in Pump Applications

Do you package pumps?

Still using risers or Fabricating raised pedestals?

If you do, the RotaChock is for you!!

Save Time

Save Time

Zero Softfoot

Zero Softfoot

For the lifcycle

For the lifcycle

Friendly Support

Friendly Support

Learn More About RotaChocks

Learn More About RotaChocks

Are you machining your pump skids / base plates, are you following API 610 recommendations, Flatness within 0.002" per foot and each plane within 0.005".

So you have machined everything to the recommended tolerance, Pump package assembled, your customer comes in and inspects the unit, its shipped to site

Installation as per API 686, requires the flatness to "dialed" back in by using baseplate jackbolts and hold-down bolts, then its and grouted in.

After grout is cured 48 hours+ inspection calls out that the flatness is no longer within recommendations and you or your customer will incur additional costs to field machine surfaces to meet flatness recommendations.

Specify RotaChocks for mounting the Driver and/or Gearbox.

and these issues will be eliminated for the life cycle !!

NO MACHINING

NO DIALING IN BASEPLATES

Zero Softfoot for life

Zero Softfoot for life

No more machining of the base plate for mounting driver / gearbox.

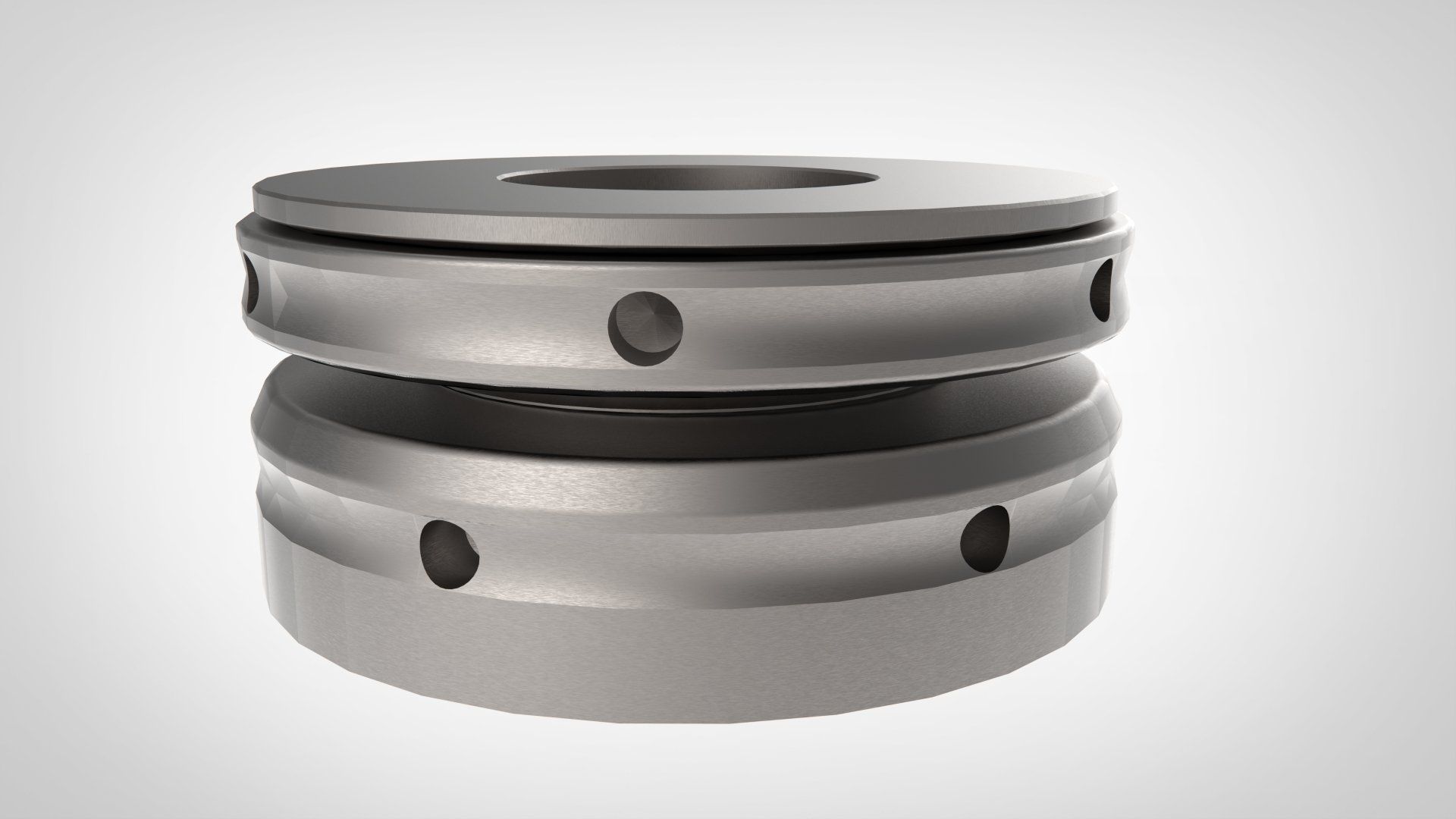

The RotaChock is a Gap Filler !!

The RotaChock is a Gap Filler !!

Carryout Alignment of jack-bolts, vertical and horizontal, set 0.002" higher than your target. Install the RotaChocks, back off the Vertical jack-bolts. Install component's hold down bolts, double check alignment. Your DONE!!