Tall Assemblies

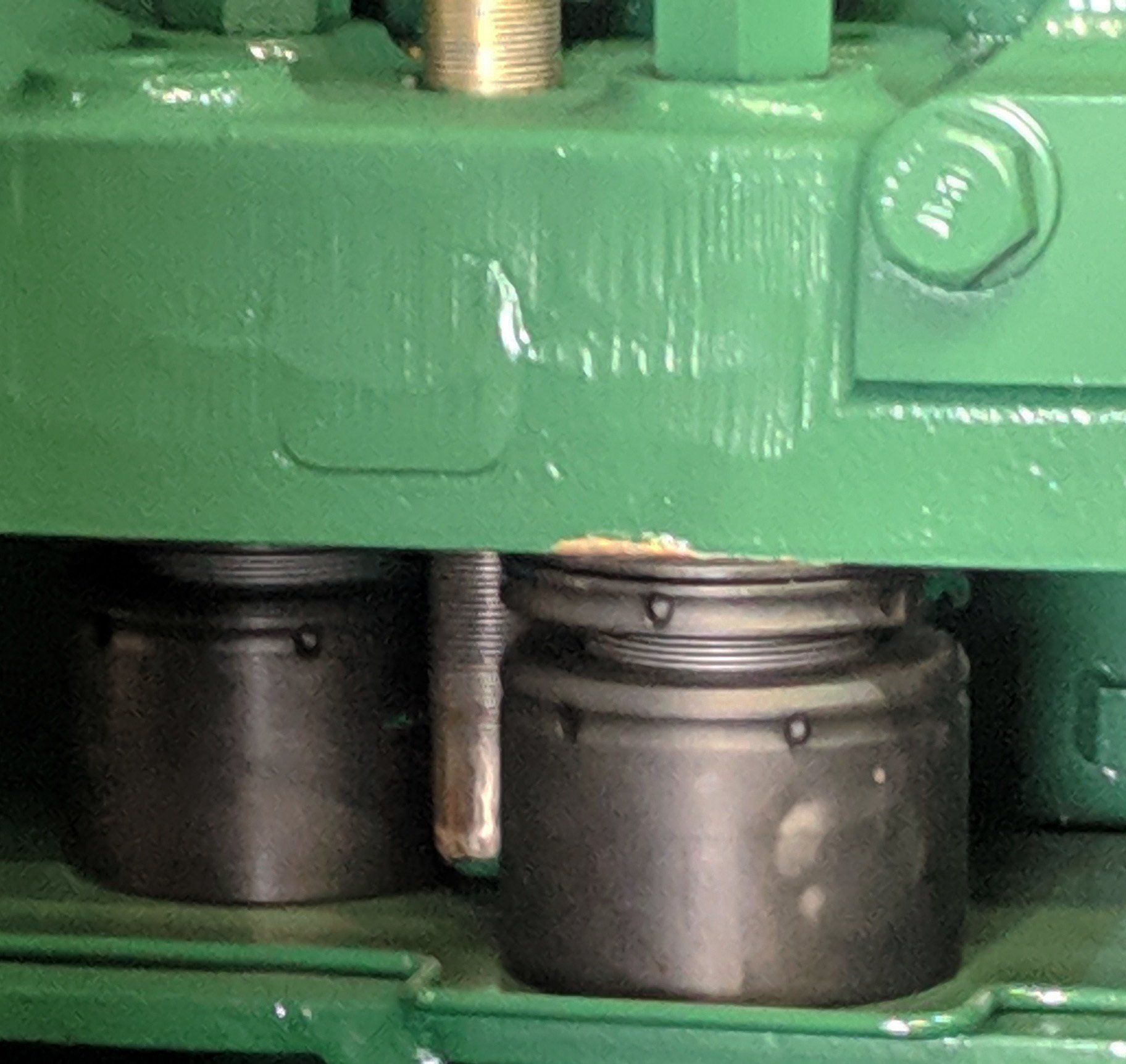

Tall Line RotaChocks

Why use Tall Line Assemblies?

Shaft center line heights between the driver and driven equipment are usually different. How does the engineer address this height difference? Usually, different height pedestals are affixed to the skid to accommodate these differences. This solution is costly as additional craftsmanship is essential to fit-up the steel work and welding required while holding the co-planer requirements for mounting surfaces. Meeting the flatness requirements is tough in the shop. But the unit still needs to be transported to the site and installed. Making the mounting areas coplanar and flat again can be costly.

Our solution is RotaChocks supplied with a taller height to suit your application!

Step one: is to simplify the design of the skid. Make the skid simple - flat!

Step two: Use the RotaChocks to take-up the shaft centerline height differences – simple, fast and zero softfoot for the lifecycle of the system.

We do have some considerations for these type of configurations. Applications that have thrust or other bolt in shear force (s) directions need attention. Our experience with ballistic, seismic or applications with complex couples is comprehensive. Let us help!